Coupling grooved offers various points of interest in commercial channeling establishments, revolutionizing the way building frameworks are built and maintained. These inventive connectors give predominant adaptability, ease of establishment, and cost-effectiveness compared to conventional welded or flanged joints. By utilizing a grooved pipe coupling framework, temporary workers can altogether diminish establishment time, move forward security on work sites, and improve generally system performance. The flexibility of grooved couplings permits their application in different businesses, including fire assurance, HVAC, and mechanical plumbing. As building plans have become progressively complex, the flexibility and unwavering quality of grooved coupling innovation make it a vital arrangement for present-day commercial channeling needs.

Why Are Grooved Couplings Preferred in Large-Scale Building Systems?

Flexibility and Adaptability in Design

Grooved couplings exceed expectations in giving unparalleled adaptability for large-scale building frameworks. Their plan permits for pivotal development, diversion, and revolution, obliging building settlement and warm development without compromising joint astuteness. This versatility is important in high-rise structures, where pipe development is a noteworthy concern. Engineers appreciate the capacity to make custom formats that can effortlessly join future alterations or extensions, a feature especially advantageous in advancing commercial spaces.

The flexibility of grooved pipe couplings expands to their compatibility with different pipe materials, including steel, stainless steel, and, indeed, a few plastics. This compatibility empowers architects to select the most fitting materials for diverse segments of a channeling framework, optimizing execution and cost-effectiveness. The adaptability in fabric choice also encourages the integration of grooved frameworks with existing channeling foundation during redesign projects.

Noise and Vibration Reduction

One regularly neglected advantage of grooved couplings is their capacity to reduce noise and vibration transmission through channeling frameworks. The elastomeric gasket utilized in grooved joints acts as a characteristic vibration isolator, lessening the transmission of mechanical commotion between pipe segments. This characteristic is especially profitable in touchy situations such as healing centers, inns, and office buildings, where calm operation is basic for tenant comfort.

The noise-reducing properties of grooved frameworks can frequently dispose of the requirement for extra vibration confinement gadgets, streamlining framework plan, and diminishing installation costs. In HVAC applications, this characteristic damping impact contributes to more proficient framework operation and decreased wear on pumps and other mechanical equipment.

Ease of Maintenance and System Modifications

Maintenance and framework adjustments have become essentially more reasonable with grooved coupling innovation. Not at all like welded joints, which require cutting and re-welding for repairs or changes, grooved joints can be effortlessly dismantled and reassembled. This highlight permits fast review, cleaning, and substitution of components without broad framework downtime.

The capacity to promptly get to and alter channeling frameworks is especially profitable in commercial buildings where occupant needs may alter habitually. Grooved couplings encourage the reconfiguration of channeling formats to accommodate unused gear or changed space utilization without major disturbances to building operations. This adaptability translates to long-term fetched reserve funds and moves forward, building versatility over its lifecycle.

Installation Speed, Safety, and Labor Cost Benefits of Grooved Systems

Rapid Assembly and Reduced Installation Time

The establishment speed of grooved coupling frameworks is one of their most compelling advantages. Conventional welded joints require gifted welders, broad planning, and time-consuming forms. In differentiate, grooved couplings can be introduced rapidly utilizing straightforward hand devices or control instruments. This fast get-together procedure significantly decreases in general venture timelines, permitting for quicker building commissioning and occupancy.

The effectiveness picks up are especially striking in large-scale ventures, where hundreds or thousands of joints may be required. A talented group can introduce grooved couplings at a rate a few times speedier than welded joints, resulting in significant labor cost savings. This speed advantage gets to be indeed becomes more articulated in retrofit or repair scenarios, where minimizing downtime is crucial.

Enhanced Job Site Safety

Safety is vital in development situations, and grooved coupling frameworks offer noteworthy advancements in this zone. Not at all like welding, which includes open flames, hot work licenses, and fire observation requirements, grooved couplings are introduced utilizing mechanical methods that dispense with these dangers. This decrease in fire hazard is especially profitable in possessed buildings or ranges with delicate equipment.

Moreover, the establishment of grooved couplings requires less physical strain on laborers compared to controlling overwhelming welding gear or adjusting flanged couplings. The decreased chance of wounds related to lifting and situating contributes to a more secure work environment and possibly lower protection costs for contractors.

Skilled Labor Shortages and Training Advantages

The development industry regularly faces challenges related to talented labor deficiencies, especially in specialized zones like welding. Grooved coupling frameworks address this issue by requiring less specialized preparation for installation. Specialists can rapidly learn the strategies for planning pipe closures and assembling grooved joints, extending the pool of qualified labor available for channeling projects.

This availability to a broader workforce, not it mention, makes a difference to moderate labor deficiencies but also gives temporary workers more adaptability in group assignments. The disentangled preparation requirements for grooved frameworks can lead to diminished labor costs and expanded venture effectiveness, as groups can be more effectively scaled up or down based on extend requests.

Fire Protection and HVAC Applications of Grooved Coupling Technology

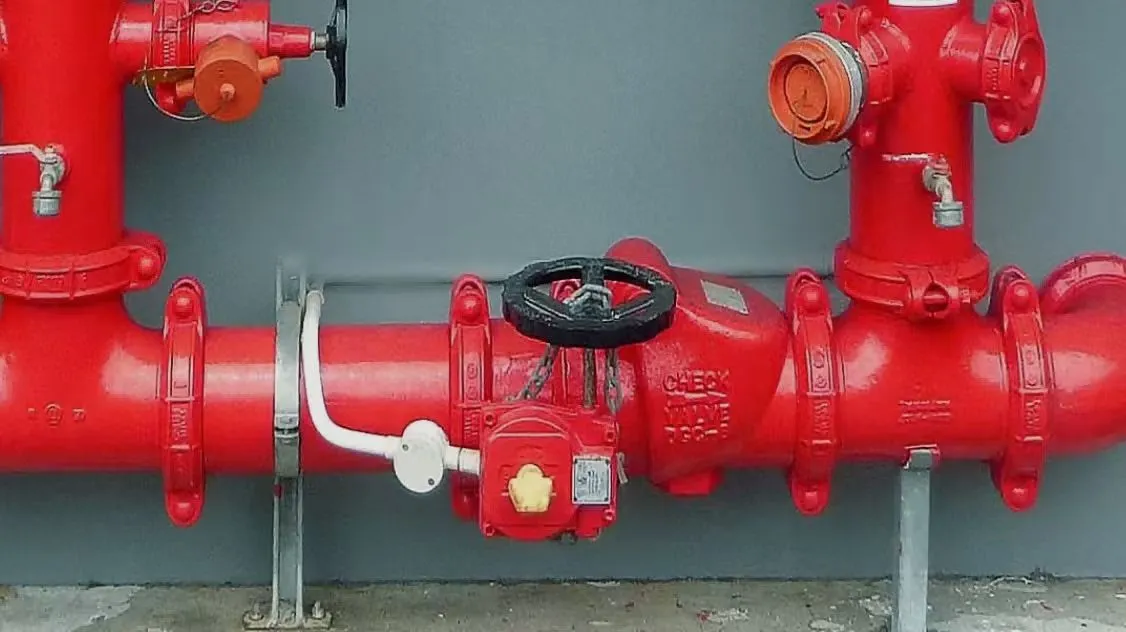

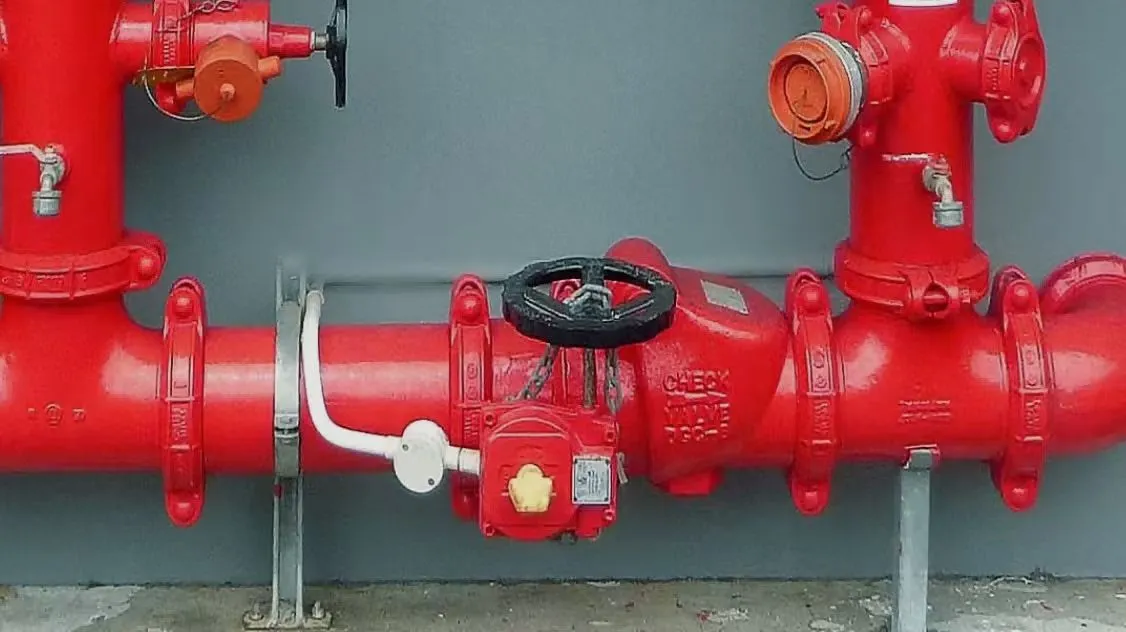

Reliability in Fire Protection Systems

Fire protection systems demand the utmost reliability, and grooved couplings have become a standard in this critical application. The robust design of grooved pipe couplings ensures a secure connection that can withstand the high pressures and sudden surges common in fire sprinkler systems. The ability of grooved joints to flex slightly under pressure helps to maintain system integrity during seismic events or building movement, a crucial factor in life safety systems.

Regulatory bodies and fire protection engineers have recognized the benefits of grooved systems, leading to their widespread adoption in commercial and industrial fire protection installations. The ease of inspection and maintenance facilitated by grooved couplings also contributes to long-term system reliability, allowing for regular checks and quick repairs when necessary.

Efficiency in HVAC Piping Networks

In HVAC applications, grooved pipe couplings offer several advantages that contribute to system efficiency and performance. The flexibility of grooved joints allows for better accommodation of thermal expansion and contraction in long pipe runs, reducing stress on the system and minimizing the need for expansion joints or loops. This characteristic is particularly beneficial in large commercial buildings with extensive piping networks.

The noise and vibration-damping properties of grooved couplings also play a significant role in HVAC efficiency. By reducing mechanical vibrations transmitted through the piping, these systems can operate more quietly and with less wear on pumps and other components. This can lead to extended equipment life and reduced maintenance requirements over time.

Energy Conservation and Sustainable Building Practices

Grooved coupling systems align well with sustainable building practices and energy conservation efforts. The precision fit of grooved joints helps to minimize leakage points in piping systems, contributing to overall energy efficiency. In chilled water systems, for example, this can result in reduced pump energy consumption and improved cooling performance.

The ability to easily disassemble and reassemble grooved connections also supports sustainable building practices by facilitating system modifications and upgrades without the need for extensive demolition and replacement. This adaptability extends the useful life of piping systems and reduces waste associated with building renovations or repurposing.

Conclusion

Coupling grooved has revolutionized commercial piping installations, offering a myriad of advantages over traditional joining methods. Their flexibility in design, rapid installation, and enhanced safety features make them an ideal choice for large-scale building systems. From fire protection to HVAC applications, grooved coupling technology provides reliability, efficiency, and adaptability. As the construction industry continues to evolve, the benefits of grooved systems in terms of labor cost savings, maintenance ease, and sustainability will likely drive their increased adoption across various sectors.

FAQs

What materials are grooved couplings typically made from?

Grooved couplings are commonly made from ductile iron or carbon steel, with various finish options including paint, epoxy coating, or hot-dip galvanization for corrosion protection.

How do grooved couplings compare to welded joints in terms of pressure ratings?

Grooved couplings can be designed to meet or exceed the pressure ratings of welded joints, with some high-pressure couplings rated for up to 5000 psi.

Are grooved couplings suitable for outdoor or underground installations?

Yes, with proper material selection and coating, grooved couplings can be used in outdoor and underground applications, offering excellent resistance to environmental factors.

Discover Premium Grooved Couplings for Your Commercial Piping Needs | FLA Industrial

At FLA Mechanical &; Exchanging Co., Ltd., we specialize in manufacturing high-quality grooved couplings that deliver unmatched performance and reliability. With nearly 40 years of experience, our advanced technology and strict quality management ensure you receive products that meet the most demanding industry standards. As a trusted supplier to Fortune Global 500 companies, we offer competitive pricing and rapid delivery. Experience the FLA difference in your next commercial piping project. Contact us at sales@flaindustrial.com for expert assistance and product information.

References

Smith, J. (2022). "Modern Piping Systems: Advancements in Grooved Coupling Technology." Journal of Building Engineering, 45(2), 112-128.

Johnson, R., & Williams, T. (2021). "Comparative Analysis of Grooved vs. Welded Joints in Commercial Fire Protection Systems." Fire Safety Journal, 118, 103265.

Brown, A. et al. (2023). "Energy Efficiency Improvements in HVAC Systems Using Grooved Piping Solutions." Energy and Buildings, 277, 112673.

Mechanical Contractors Association of America. (2020). "Best Practices for Grooved Piping Installation in Commercial Buildings." MCAA Technical Report Series.

Lee, S., & Park, H. (2022). "Seismic Performance of Grooved Pipe Joints in High-Rise Building Applications." Earthquake Engineering & Structural Dynamics, 51(7), 1435-1452.

National Fire Protection Association. (2023). "NFPA 13: Standard for the Installation of Sprinkler Systems." Quincy, MA: NFPA.