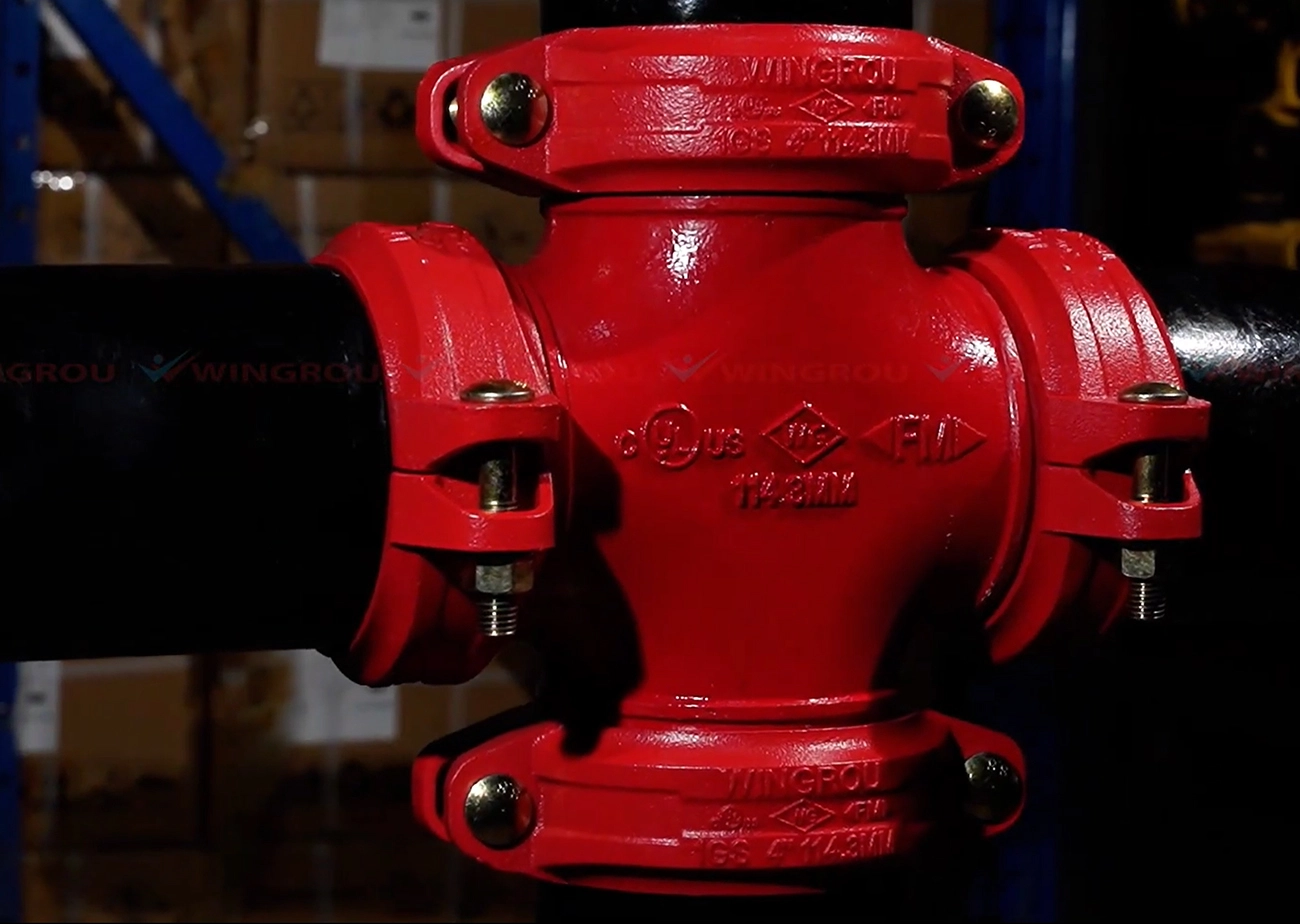

Grooved Cross

Application: Branching or merging of four-way firefighting pipelines

Finish: Painted or Epoxy Coated

Origin: China

Manufacturing Process: Casting, Machining

Certification: ISO9001, CE

Grooved Cross - Multi-Directional Pipe Connection Solution

When you require solid multi-directional associations in your channeling framework, our Grooved Cross fitting conveys the execution you request. This four-way association fitting is expertly built from strong bendable press to handle the most complex mechanical channeling applications. Whether you're working with water, oil, or gas pipelines, our item gives the secure branching arrangement your extend requires.

Our item fitting combines progressed fabricating with time-tested materials to guarantee long-lasting execution. Each unit highlights four accurately machined furrowed associations that make secure joints whereas rearranging establishment. You'll appreciate how this plan diminishes get together time whereas keeping up the basic astuteness your framework needs.

Why Choose Us?

24-48 Hour Reaction Time

When you require estimating, weight details, or 3D plans, we react inside 24-48 hours. No more holding up days for basic requests.

Full Specialized Support

From starting 3D plan confirmation to generation advance upgrades, we keep you educated each step of the way.

ISO and CE Certified Quality

Every item meets universal guidelines for security and execution. You get solid quality supported by recognized certifications.

Product Specifications

| Parameter | Specification |

|---|---|

|

Material |

Ductile Iron |

|

Connection Type |

Four-way Grooved |

|

Available Sizes |

2" - 12" (50mm - 300mm) |

|

Working Pressure |

Up to 300 PSI (2.07 MPa) |

|

Temperature Range |

-20°C to 120°C |

|

Finish Options |

Painted or Epoxy Coated |

|

Manufacturing Process |

Casting + Precision Machining |

|

Thread Standard |

ANSI/AWWA C606 |

|

Wall Thickness |

Standard and Heavy Duty |

|

Weight Range |

2.5kg - 25kg (size dependent) |

Usage Scenarios

Industrial Water Systems

Perfect for water treatment plants and conveyance systems where you require to part primary lines into numerous branches.

Fire Security Systems

Essential for sprinkler frameworks requiring different directional nourishes from a single supply line.

Oil and Gas Pipelines

Ideal for making conveyance focuses in petroleum handling offices and refineries.

HVAC Applications

Excellent for warming and cooling frameworks that require four-way liquid distribution.

Marine and Offshore

Reliable execution in cruel marine situations with legitimate coating selection.

Product Features

Four Furrowed Connections

Each outlet highlights precision-machined grooves for secure coupling associations that won't extricate beneath pressure.

Ductile Press Construction

Superior quality and erosion resistance compared to standard cast press alternatives.

Easy Installation

Grooved associations dispense with threading prerequisites, decreasing establishment time by up to 50%.

Versatile Orientation

Configure your item in any position to meet your particular format requirements.

Pressure Tested

Every fitting experiences weight testing to guarantee it meets or surpasses appraised specifications.

Custom Solutions Available

Your channeling framework is interesting, and in some cases you require fittings that coordinate. We specialize in making custom special-shaped parts that standard catalogs can't provide.

Custom Sizes

Need non-standard dimensions? We'll manufacture Grooved Crosse to your exact specifications.

Different situations require distinctive materials. We can work with different combinations and coatings.

Modified Configurations

From calculated outlets to strengthened plans, we'll build the arrangement your application demands.

3D Plan Services

Before generation, we'll make nitty gritty 3D models so you can visualize and favor your custom fitting.

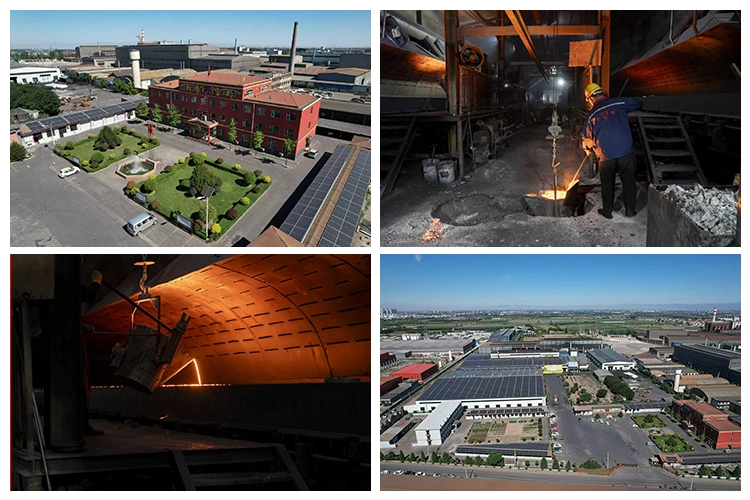

Quality Control

Material Verification

Every group of bendable press experiences chemical composition investigation to guarantee it meets our strict standards.

Dimensional Inspection

Precision measuring gear confirms that groove measurements and outlet situating meet specifications.

Pressure Testing

Each item is weight tried to 1.5 times its working weight rating.

Surface Wrap up Inspection

Coating thickness and grip testing guarantees your fittings will stand up to erosion for years.

Documentation

Complete material certificates and test reports accompany every shipment for your records.

Certifications

Our fabricating office and items keep up globally recognized certifications:

- ISO 9001 Quality Administration Framework - Guaranteeing reliable quality in each product

- CE Item Security Certification - Assembly European security measures for worldwide acceptance

These certifications illustrate our commitment to quality and donate you certainty in your buy decision.

FAQ

Q: What's the maximum working pressure for your product fittings?

A: Our standard fittings handle up to 300 PSI (2.07 MPa). For higher pressure applications, we offer heavy-duty versions.

Q: What coating options do you recommend for outdoor installations?

A: For outdoor use, we recommend epoxy coating for superior corrosion resistance compared to standard paint finishes.

Q: Do you provide installation guidance for your fittings?

A: Yes, we supply detailed installation instructions and technical drawings with every order. Our technical team is also available for consultation.

Contact Us

Ready to find the perfect Grooved Cross solution for your project? Our technical team is standing by to help you select the right specifications and answer any questions.

Email: sales@flaindustrial.com

We'll react to your request inside 24-48 hours with nitty gritty estimating, specialized determinations, and conveyance data. Whether you require standard fittings or custom arrangements, we're here to make your extend effective.

Send your inquiry now and start your cooperation with our experienced team.