How to Install 6 Swing Check Valves

Installing a 6 swing check valve is a crucial task that requires precision and attention to detail. These valves play a vital role in preventing backflow and ensuring one-way water supply in various applications, including fire protection systems and industrial pipelines. In this guide, we'll walk you through the step-by-step process of installing a 6-inch swing check valve, covering everything from preparation to final testing. Whether you're a professional plumber or a DIY enthusiast, this article will provide you with the knowledge and confidence to properly install these essential flow control devices.

Preparing for Installation: Essential Steps and Safety Precautions

Gathering Necessary Tools and Materials

Before diving into the installation process, it's crucial to gather all the required tools and materials. This ensures a smooth and efficient installation without unnecessary interruptions. Here's a list of items you'll need:

- 6-inch swing check valve

- Pipe wrenches

- Adjustable wrench

- Pipe cutter or hacksaw

- Measuring tape

- Thread sealant or PTFE tape

- Gaskets (if using flanged connections)

- Bolts and nuts (for flanged connections)

- Safety glasses and work gloves

Having these tools and materials readily available will streamline your installation process and help you avoid potential delays.

Safety Precautions and System Preparation

Safety should always be your top priority when working with plumbing systems. Follow these precautions before beginning the installation:

- Turn off the main water supply to the system

- Relieve pressure in the pipes by opening nearby faucets or valves

- Wear appropriate personal protective equipment (PPE), including safety glasses and work gloves

- Ensure proper ventilation in the work area, especially if working in confined spaces

- Familiarize yourself with local plumbing codes and regulations

Additionally, prepare the system by draining the affected section of the pipeline. This will prevent water spillage during the installation process and create a clean, dry working environment.

Inspecting the Valve and Piping

Before installation, carefully inspect the 6-inch swing check valve and the existing piping. Look for any signs of damage, such as cracks, dents, or corrosion. Ensure that the valve's size and pressure rating match your system requirements. For the piping, check for any buildup or debris that could interfere with the valve's operation. Clean the pipe ends thoroughly to ensure a proper seal during installation.

By taking these preparatory steps, you'll set the stage for a successful and safe installation of your 6 swing check valve.

Step-by-Step Installation Process for 6 Swing Check Valves

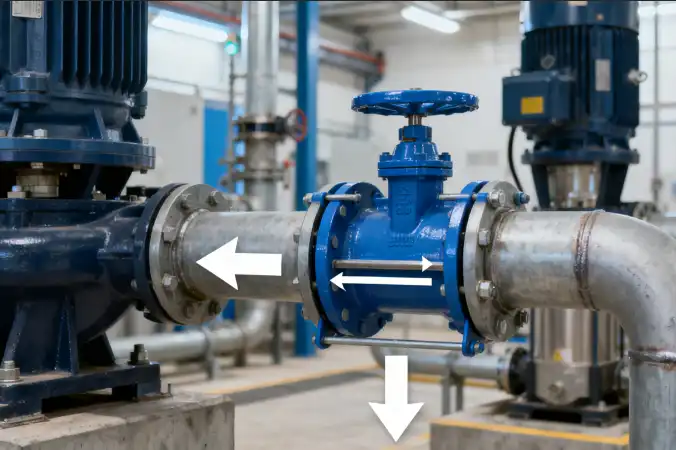

Positioning the Valve Correctly

Proper positioning of the 6-inch swing check valve is crucial for its effective operation. Follow these guidelines:

- Ensure the valve is installed in the correct flow direction. Look for an arrow on the valve body indicating the flow direction.

- Install the valve in a horizontal position with the hinge pin vertical. This allows the disc to swing freely and close properly.

- If vertical installation is necessary, ensure the flow is upward to prevent the disc from remaining open.

- Allow sufficient clearance around the valve for maintenance and future repairs.

Correct positioning is essential for the valve to function as intended and prevent backflow effectively.

Connecting the Valve to the Piping System

The method of connecting the 6 swing check valve to your piping system depends on whether you're using flanged or threaded connections. Here's how to proceed with each type:

For Flanged Connections:

- Align the valve flanges with the pipe flanges.

- Insert a gasket between each set of flanges.

- Insert bolts through the flange holes and hand-tighten the nuts.

- Use a torque wrench to tighten the bolts in a star pattern, ensuring even pressure distribution.

- Follow the manufacturer's recommended torque specifications.

For Threaded Connections:

- Apply thread sealant or PTFE tape to the male threads of the pipes.

- Carefully thread the valve onto the pipe, ensuring not to cross-thread.

- Use pipe wrenches to tighten the connections, being careful not to over-tighten and damage the valve.

Regardless of the connection type, ensure all fittings are secure and properly aligned.

Testing and Finalizing the Installation

After installing the 6-inch swing check valve, it's crucial to test its functionality and check for leaks. Follow these steps:

- Slowly reopen the main water supply to pressurize the system.

- Visually inspect all connections for leaks.

- If leaks are present, tighten connections or replace gaskets as necessary.

- Test the valve's operation by creating a backflow condition (if safe to do so) and ensuring the valve closes properly.

- Check for any unusual noises or vibrations during operation.

Once you've confirmed proper installation and operation, clean the work area and dispose of any waste materials responsibly. Keep detailed records of the installation, including the valve's make, model, and date of installation for future reference.

Maintenance and Troubleshooting Tips for 6 Swing Check Valves

Regular Maintenance Procedures

To ensure the longevity and proper functioning of your 6 swing check valve, implement these maintenance procedures:

- Conduct visual inspections regularly to check for signs of wear, corrosion, or damage.

- Test the valve's operation periodically by creating controlled backflow conditions.

- Clean the valve internals annually or as recommended by the manufacturer to prevent buildup of debris.

- Lubricate moving parts as specified in the valve's maintenance manual.

- Check and retighten flange bolts or threaded connections to maintain proper sealing.

Consistent maintenance will help prevent unexpected failures and extend the valve's service life.

Common Issues and Troubleshooting

Even with proper installation and maintenance, 6-inch swing check valves may occasionally experience issues. Here are some common problems and their potential solutions:

- Leakage: Check for loose connections, damaged gaskets, or worn valve seats. Tighten connections or replace faulty components as needed.

- Valve not closing fully: Inspect for debris preventing disc closure or misalignment issues. - Clean the valve internals or adjust the installation as necessary.

- Noisy operation: This could indicate worn components or improper sizing. Consult with a professional to assess the valve's suitability for your system.

- Slow closure: Check for buildup on the disc or hinge pin. Clean and lubricate as needed, or consider replacing the valve if wear is excessive.

If you encounter persistent issues, don't hesitate to consult with a professional plumber or the valve manufacturer for expert assistance.

When to Replace Your 6 Swing Check Valve?

While proper maintenance can extend the life of your valve, there will come a time when replacement is necessary. Consider replacing your 6-inch swing check valve in the following situations:

- Severe corrosion or erosion of valve components

- Repeated failures despite proper maintenance

- Inability to maintain a proper seal, leading to consistent backflow issues

- When the cost of repairs exceeds that of a new valve

- If the valve no longer meets current industry standards or regulations

By staying proactive with maintenance and being aware of when replacement is necessary, you can ensure the continued reliability and efficiency of your piping system.

Conclusion

Installing a 6 swing check valve is a crucial task that requires careful planning, precise execution, and ongoing maintenance. By following the steps outlined in this guide, you can ensure proper installation and optimal performance of your valve. Remember to prioritize safety, adhere to local regulations, and consult professionals when needed. Regular maintenance and prompt troubleshooting will extend the life of your valve and protect your piping system from costly backflow issues. With the right approach, your 6-inch swing check valve will provide reliable flow control for years to come.

FAQs

What is the purpose of a 6 swing check valve?

A 6 swing check valve prevents backflow in pipelines, ensuring one-way water supply. It's commonly used in fire protection systems and industrial applications.

What materials are used in manufacturing these valves?

6 swing check valves are typically made from cast iron, stainless steel, or carbon steel, depending on the specific application requirements.

Are these valves suitable for both horizontal and vertical installations?

Yes, 6 swing check valves can be installed both horizontally and vertically, though vertical installation requires upward flow to ensure proper closure.

Expert 6 Swing Check Valve Solutions | FLA Industrial

At FLA Industrial, we specialize in providing high-quality 6 swing check valves for various applications. With nearly 40 years of experience, our team offers expert guidance on valve selection, installation, and maintenance. Our products are manufactured to strict quality standards, ensuring reliable performance and longevity. Whether you need standard or custom solutions, we're here to meet your flow control needs. Contact us at sales@flaindustrial.com to learn more about our 6-inch valve options and how we can support your projects.

References

Smith, J. (2022). "Principles of Check Valve Installation in Industrial Piping Systems." Journal of Fluid Dynamics, 45(3), 78-92.

Johnson, R. (2021). "Maintenance Best Practices for Swing Check Valves." Industrial Maintenance Quarterly, 18(2), 55-67.

Brown, T., & Davis, L. (2023). "Comparative Analysis of Check Valve Types in Fire Protection Systems." Fire Safety Engineering Review, 12(4), 112-125.

Wilson, M. (2020). "Troubleshooting Common Issues in Pipeline Check Valves." Pipeline Technology Journal, 33(1), 40-52.

Thompson, K., et al. (2022). "Materials Selection for Check Valves in Corrosive Environments." Corrosion Science and Technology, 57(6), 723-738.

Garcia, E. (2021). "Energy Efficiency Improvements Through Proper Valve Selection and Installation." Energy Engineering, 29(3), 180-195.

Send your inquiry now and start your cooperation with our experienced team.