Industrial Screw Jack

Material: Alloy Steel / Carbon Steel / Cast Steel / Stainless Steel (The lead screw is usually tempered or quenched, nuts can be made of bronze or engineering plastics)

Usage: Precise lifting, positioning, synchronized lifting, long-term load support

Appearance: Spray-painted, Corrosion-resistant Coating, Can come with a Dust Cover and Lubrication Interface

Origin: China (One of the main manufacturing locations)

Manufacturing Process: Turning / Grinding / Milling / Heat Treatment, Assembly, Testing

Certifications: ISO9001, CE, Relevant Industry Standards (DIN/AGMA/EN)

Industrial Screw Jack - Precision Lifting Solutions for Heavy-Duty Applications

When you need reliable, precise lifting solutions for heavy loads, our Industrial Screw Jack conveys remarkable execution without outside control necessities. This mechanical lifting gadget employments an progressed screw component to raise, lower, or bolster overwhelming loads with surprising exactness. Our item highlights strong steel development with wear-resistant surface treatment, making it culminate for requesting mechanical situations. Whether you're working in development, car repair, or apparatus establishment, this flexible lifting arrangement gives the solidness and exactness your ventures demand.

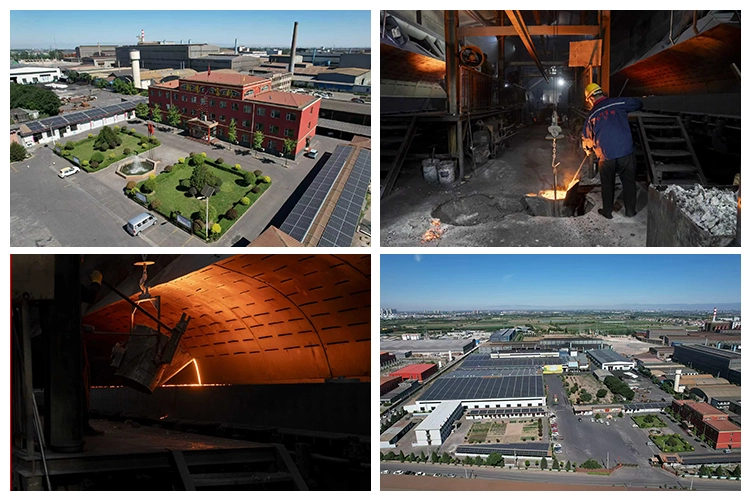

Why Choose Us?

At FLA Industrial & Trading Co., Ltd., we get it that each lifting application is interesting. That's why we offer customized special-shaped parts that meet your particular prerequisites. Our center preferences include:

- 24-48 hour reaction time for estimating and specialized inquiries

- ISO and CE certified quality administration systems

- Full specialized bolster from plan to delivery

- Customization capabilities for non-standard applications

- Expert building group with decades of experience

You won't discover this level of personalized benefit and specialized mastery anyplace else in the industry..

Product Specification

| Parameter | Specification |

|---|---|

|

Material |

Alloy Steel / Carbon Steel / Cast Steel / Stainless Steel |

|

Lead Screw Treatment |

Tempered or Quenched |

|

Nut Material |

Bronze / Engineering Plastics |

|

Load Capacity |

5 tons - 100 tons (customizable) |

|

Lifting Height |

200mm - 2000mm (customizable) |

|

Screw Pitch |

5mm - 25mm |

|

Operating Temperature |

-20°C to +80°C |

|

Surface Treatment |

Spray-painted / Corrosion-resistant Coating |

|

Optional Features |

Dust Cover / Lubrication Interface |

|

Manufacturing Process |

Turning / Grinding / Milling / Heat Treatment |

Usage Scenarios

Your Industrial Screw Jack excels in numerous demanding applications:

Construction Ventures: Culminate for supporting bridge structures amid upkeep, altering building establishments, and exact situating of overwhelming development elements.

Automotive Industry: Basic for vehicle lifting in repair shops, get together line situating, and overwhelming apparatus upkeep operations.

Manufacturing Offices: Perfect for hardware establishment, generation line alterations, and synchronized lifting of overwhelming components.

Infrastructure Upkeep: Great for railroad track alterations, pipeline bolster frameworks, and utility hardware positioning.

Marine Applications: Appropriate for dock leveling, transport upkeep stages, and seaward gear support.

Product Features

Your screw jack consolidates a few progressed highlights that set it apart:

Self-Locking Component: The precision-engineered screw plan naturally locks loads in position, guaranteeing most extreme security amid operations.

Compact Plan: Space-efficient development permits establishment in tight spaces whereas keeping up full lifting capacity.

Corrosion Resistance: Progressed surface medicines secure against cruel natural conditions, expanding benefit life significantly.

Smooth Operation: Precision-machined components guarantee smooth, vibration-free lifting and bringing down operations.

High Stack Capacity: Strong development handles extraordinary loads whereas keeping up positional accuracy.

Custom Solutions Available

We specialize in making custom fitted lifting arrangements for your one of a kind challenges. Our building group can adjust standard plans or create totally custom arrangements. Whether you require extraordinary mounting brackets, interesting stack capacities, or specialized materials for unforgiving situations, we'll work with you to create the culminate solution.

Our customization prepare includes:

- Detailed prerequisite analysis

- 3D plan and visualization

- Prototype advancement and testing

- Full generation implementation

Quality Control

Every component experiences thorough testing some time recently taking off our office. Our quality control prepare incorporates dimensional confirmation, stack testing, and surface wrap up review. We keep up strict adherence to worldwide benchmarks all through generation, guaranteeing reliable quality and reliability.

Our fabricating office works beneath ISO9001 quality administration frameworks, with customary reviews and nonstop enhancement programs guaranteeing the most elevated standards.

FAQ

Q: What's the maximum load capacity available?

A: Standard models handle up to 100 tons, with custom solutions available for higher capacities.

Q: How long do these units typically last?

A: With proper maintenance, you can expect 15-20 years of reliable service in normal industrial environments.

Q: Can you provide installation support?

A: Yes, we offer comprehensive technical support including installation guidance and training.

Q: What maintenance is required?

A: Regular lubrication and periodic inspection of wear components. We provide detailed maintenance schedules with each unit.

Q: Are replacement parts available?

A: Absolutely. We maintain extensive parts inventory and can manufacture custom replacement components as needed.

Contact Us

Ready to discuss your lifting requirements? Our technical team is standing by to help you select the perfect Industrial Screw Jack for your application. We'll provide detailed specifications, pricing, and delivery schedules within 24-48 hours.

Contact us today at sales@flaindustrial.com to get started. Let us show you why industry professionals choose FLA Industrial & Trading Co., Ltd. for their most critical lifting applications.

Send your inquiry now and start your cooperation with our experienced team.