Grooved Reducers

Application: Connection between different pipe diameters in firefighting systems

Finish: Painted, Epoxy Resin Coating

Origin: China

Manufacturing Process: Casting, Machining

Certification: ISO9001, CE, UL/FM

Grooved Reducers - Professional Pipe Fitting Solutions

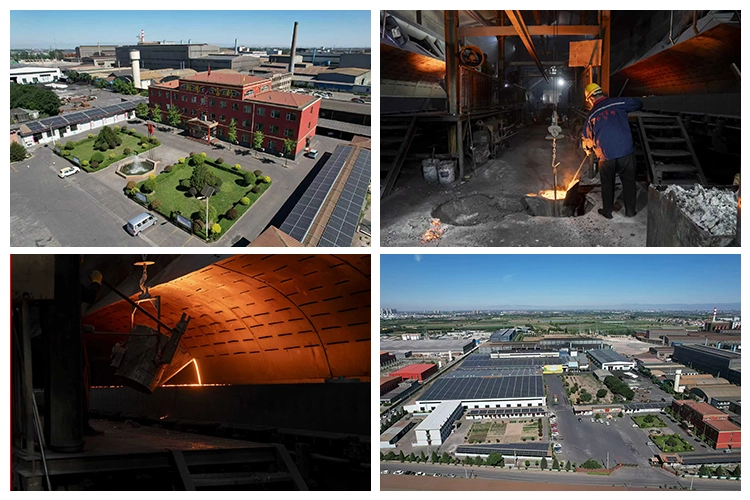

When your piping system requires smooth transitions between different pipe diameters, Grooved Reducers provide the perfect solution. These specialized pipe fittings are engineered to facilitate seamless flow while minimizing pressure loss in your fluid transport systems. At FLA Industrial & Trading Co., Ltd., we fabricate high-quality item utilizing premium pliable press materials, guaranteeing strength and dependable execution in requesting applications. Our broad stock and custom fabricating capabilities cruel you get precisely what you require, when you require it.

Our pipe fitting arrangements are especially important in firefighting frameworks, mechanical channeling, and plumbing applications where breadth moves are fundamental. With smooth inner surfaces and vigorous development, these reducers keep up ideal stream characteristics whereas giving long-lasting benefit life.

Why Choose Us?

Customization Greatness: Our center quality lies in fabricating special-shaped parts and non-standard arrangements. Whether you require interesting measurements or particular auxiliary adjustments, we adjust to your correct requirements.

Quality Confirmation: Each item meets worldwide benchmarks through our ISO9001 certified quality administration framework and CE security compliance.

Technical Back: From starting 3D plan confirmation to generation advance upgrades, our group gives comprehensive back all through your project.

24-48 Hour Reaction: Require estimating, specialized determinations, or plan interview? We react inside 24-48 hours, quickening your decision-making process.

Product Specifications

| Specification | Details |

|---|---|

|

Material |

Ductile Iron |

|

Manufacturing Process |

Casting + Precision Machining |

|

Finish Options |

Painted, Epoxy Resin Coating |

|

Pressure Rating |

Up to 300 PSI |

|

Temperature Range |

-20°C to 110°C |

|

Connection Type |

Grooved End |

|

Size Range |

1" to 12" (Custom sizes available) |

|

Standard Compliance |

AWWA C606, ASTM A536 |

|

Weight |

Varies by size (Contact for specifics) |

|

Origin |

China |

Usage Scenarios

Firefighting Frameworks: Fundamental for interfacing sprinkler lines of diverse breadths, guaranteeing ideal water stream and weight dissemination all through fire assurance networks.

Industrial Channeling: Culminate for prepare channeling where hardware associations require distinctive pipe sizes, keeping up framework productivity and lessening turbulence.

HVAC Applications: Perfect for warming and cooling frameworks where ductwork and channeling moves are fundamental for legitimate stream distribution.

Municipal Water Frameworks: Commonly utilized in water dispersion systems where primary lines interface to benefit lines of shifting diameters.

Building Plumbing: Appropriate for commercial and private plumbing frameworks requiring smooth moves between diverse pipe sizes.

Product Features

Smooth Stream Move: Designed inside geometry minimizes turbulence and weight misfortune, keeping up framework efficiency.

Durable Development: Pliable press fabric gives amazing strength-to-weight proportion and erosion resistance.

Easy Establishment: Furrowed conclusion associations empower speedy, secure gathering without welding or threading.

Versatile Coating Choices: Select from painted or epoxy tar wraps up to coordinate your particular natural requirements.

Precision Fabricating: Progressed casting and machining forms guarantee reliable measurements and dependable performance.

Leak-Resistant Plan: Legitimately built fixing surfaces avoid framework spillage and keep up weight integrity.

Custom Solutions Available

Your unique projects deserve tailored solutions. We specialize in manufacturing custom Grooved Reducers that meet your exact specifications.Whether you require non-standard measurements, uncommon materials, or special arrangements, our building group works closely with you to create the culminate solution.

Our customization handle incorporates nitty gritty 3D modeling, execution confirmation, and model advancement. From concept to conveyance, we keep up clear communication and give normal advance updates.

Quality Control

Quality isn't just a promise – it's our standard practice. Our comprehensive quality management system ensures every product meets stringent performance requirements.

Material Testing: We confirm chemical composition and mechanical properties of all crude materials some time recently generation begins.

Dimensional Assessment: Exactness measuring gear affirms all measurements meet indicated tolerances.

Pressure Testing: Each clump experiences weight testing to confirm basic astuteness and spill resistance.

Surface Quality: Visual and material reviews guarantee coating consistency and surface wrap up quality.

Documentation: Total traceability records go with each shipment, giving full generation history.

Certifications

Our commitment to quality is approved through universally recognized certifications:

- ISO9001: Quality administration framework certification guaranteeing steady item quality

- CE: European security compliance marking

- UL/FM: Fire security and execution certifications for firefighting applications

These certifications illustrate our devotion to assembly worldwide benchmarks and giving dependable items for basic applications.

Frequently Asked Questions

Q: What's the difference between painted and epoxy resin coatings?

A: Painted finishes provide standard corrosion protection for most applications. Epoxy resin coatings offer superior chemical resistance and durability for harsh environments.

Q: Can you manufacture reducers for non-standard pipe sizes?

A: Yes, custom sizing is one of our specialties. We can manufacture product for virtually any diameter combination you require.

Q: Do you provide 3D drawings before production?

A: Absolutely. We provide detailed 3D models for approval before beginning custom production, ensuring the final product matches your exact requirements.

Q: What pressure ratings are available?

A: Standard ratings up to 300 PSI are available. Higher pressure applications can be accommodated through custom engineering.

Contact Us

Ready to discuss your pipe fitting requirements? Our technical team is here to help you select the right solution for your application.

Email: sales@flaindustrial.com

Contact us today for pricing, technical specifications, or custom design consultation. We're committed to providing the expertise and Grooved Reducers you need for successful project completion.

Send your inquiry now and start your cooperation with our experienced team.